Elevating Efficiency and Purity in Industrial Processes

In process manufacturing, the integrity of air and fluid systems is critical. Ensuring the purity of these elements enhances operational efficiency, extends equipment lifespan and ensures end products' quality. Parker Filtration, a leader in advanced filtration technology, offers a comprehensive suite of products designed to meet the rigorous demands of modern industrial applications. At Relevant Industrial, we proudly partner with Parker to deliver these exceptional solutions to our clients, enabling them to achieve superior efficiency, cost savings, and environmental compliance.

Benefits of Parker Filtration Technologies

Parker Filtration products are engineered to effectively remove contaminants, ensuring smooth and uninterrupted operation of machinery and systems. By maintaining cleaner processes, these products help reduce wear and tear, thereby enhancing overall operational efficiency. For instance, the use of high-efficiency filters can significantly lower the particle load in hydraulic fluids, leading to improved performance and longevity of hydraulic systems.

The reliability of Parker’s filtration solutions translates into substantial cost savings. By minimizing maintenance requirements and extending the service life of equipment, businesses can reduce both direct and indirect costs. For example, Parker’s Gas Turbine Filtration systems are known to reduce the frequency of turbine overhauls, resulting in significant maintenance cost reductions and increased turbine availability.

The purity of air and fluids is critical in many industrial processes. Parker’s filtration products ensure that contaminants are effectively removed, resulting in higher quality end products and consistent performance. In sectors like pharmaceuticals and semiconductor manufacturing, where even the smallest impurities can cause significant issues, Parker’s High Purity Filter Cartridges are essential for maintaining the required levels of cleanliness.

Clean processes contribute to environmental protection by reducing emissions and waste. Parker’s filtration solutions help industries meet stringent environmental regulations and sustainability goals. For instance, their advanced filtration technologies for compressed natural gas (CNG) systems ensure that harmful contaminants are removed, thus reducing environmental impact.

Parker’s filtration products are versatile and suitable for a wide range of applications, from industrial manufacturing to commercial settings. This flexibility makes them an ideal choice for diverse operational needs, whether it's in power generation, food and beverage production, or laboratory environments.

Types of Parker Filtration Products

Parker offers a comprehensive range of filtration products designed to tackle various contaminants and operational challenges. Their portfolio includes filters, which are available in various configurations to remove particulate and molecular contaminants, ensuring the purity of air and fluids in a wide range of applications. Additionally, they offer separators, which are used to separate liquid and gas contaminants from process streams, enhancing the efficiency and reliability of industrial systems. Parker purifiers are engineered to deliver high purity levels, which is critical for processes where even the smallest contaminants can cause serious issues.

How Parker Filtration Solutions Improve Industrial Processes

A leading semiconductor manufacturer implemented Parker’s High Purity Filter Cartridges in their cleanroom processes. The result was a 20% increase in product yield due to reduced contamination levels, along with a 15% reduction in maintenance costs. This improvement in process efficiency led to significant cost savings and enhanced product quality. Another example is a power generation facility that integrated Parker’s Gas Turbine Filtration system into their operations. The facility experienced a 10% improvement in turbine efficiency, a reduction in maintenance frequency, and a notable decrease in downtime. These benefits translated into substantial cost savings and increased reliability of the power generation process.

Why Choose Relevant Industrial for Parker Filtration Products

At Relevant Industrial, we combine technical expertise with a deep understanding of our clients’ needs to deliver tailored filtration solutions. Our team of experts provides comprehensive support, from initial consultation to implementation and ongoing maintenance.

Whether it’s a unique application or a complex system integration, our engineers work closely with clients to develop customized solutions that meet their exact requirements. Our proven track record of successful partnerships and project implementations underscores our commitment to delivering high-quality solutions that drive efficiency, improve product quality, and reduce operational costs.

By leveraging our expertise and Parker’s innovative products, we enable our clients to enhance efficiency, ensure product quality, and achieve significant cost savings. Contact us today to learn more about how Parker Filtration can benefit your business and to explore our comprehensive range of products and services. Contact us today to schedule a consultation or request further information!

Product Information

Parker’s Process Nitrogen Generators

Parker Process Nitrogen Generators offer on-site nitrogen production through advanced Hollow Fiber Membrane and Pressure Swing Adsorption (PSA) technologies. The HFX, MB, and DB Series nitrogen generators provide efficient solutions for industries needing a clean, dry, and inert gas. Nitrogen is widely used to prevent oxidation, bacterial growth, and the risk of combustion across sectors like food, chemicals, electronics, and oil & gas.

Traditionally, nitrogen was supplied via high-pressure cylinders or liquid tanks, which were expensive, wasteful, and posed safety risks. Parker’s nitrogen generators offer a more cost-effective, safer alternative by producing nitrogen directly from compressed air. These systems can deliver continuous nitrogen supply with purities ranging from 95% to 99%, eliminating the need for gas deliveries and storage. Parker’s generators provide significant savings, with capital payback achievable in as little as 12 months, making them an ideal choice for industries aiming for efficiency and safety.

Lab Gas Generators

Parker's Lab Gas Generators provide a reliable and consistent source of high-purity gas for laboratory applications. These generators are crucial for analytical instruments and chromatography, ensuring accurate and reliable results. Benefits include improved safety, reduced operational costs, and easy integration into laboratory settings. Key features and benefits encompass consistent high purity gas supply, compact and user-friendly design, enhanced safety with on-demand gas production, cost-effective operation, and easy integration with laboratory equipment. They are used in analytical instrumentation, chromatography, research and development laboratories, and biotech and pharmaceutical labs.

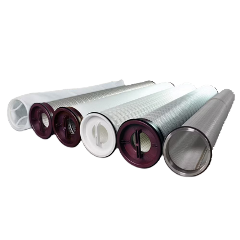

High Purity Filter Cartridges

These filter cartridges are designed to deliver exceptional filtration efficiency and durability. They are ideal for critical applications in semiconductor manufacturing, pharmaceuticals, and other industries where high purity levels are essential. These cartridges offer long service life and superior contaminant removal, ensuring optimal process performance. Key features and benefits include superior filtration efficiency, long service life, high contaminant holding capacity, low pressure drop, and compatibility with aggressive chemicals. Applications include semiconductor manufacturing, pharmaceutical production, food and beverage processing, and industrial water treatment.

CNG Filter Houses

Parker’s CNG Filter Houses are robust solutions for compressed natural gas systems. These filter houses are designed to handle the demanding conditions of CNG applications, providing reliable contaminant removal and ensuring the safe and efficient operation of refueling stations and transportation systems. Key features and benefits include high robustness and reliability, efficient contaminant removal, long service life, easy maintenance, and compliance with industry standards. Applications include CNG refueling stations, CNG transportation, industrial CNG applications, and power generation.

Balston Compressed Air & Gas Filtration

Balston Compressed Air and Gas Filters are designed to protect equipment and sensitive instruments from contaminants like dirt, water, and oil commonly found in compressed air systems. These filters offer exceptional efficiency, removing 99.99% of 0.01-micron particles and droplets. This high level of filtration reduces downtime, maintenance costs, and product rejection while extending the life of equipment.

Key features include long filter cartridge life, low pressure drop, and the ability to service flow ranges from small to large-scale operations. These filters come in a range of sizes and are shipped ready-to-install, complete with a filter cartridge, automatic drain, and differential pressure indicators. Common applications include protecting desiccant and refrigerant air dryers, removing oil and water at the source with mainline filters, and safeguarding sensitive instruments and pneumatic machinery with point-of-use filters.