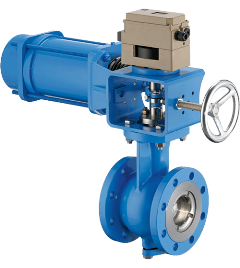

Valve Actuation

Valve actuation is essential for controlling the flow and pressure within various industrial systems. It involves using actuators to automate valve operation, enhancing system efficiency, reliability, and safety.

Automating valve operations brings significant benefits to industrial processes. Increased efficiency is achieved by reducing manual intervention, allowing for faster and more precise control, thus optimizing overall process performance. Enhanced safety is another critical advantage, as automated systems can quickly respond to emergencies, mitigating risks and protecting both personnel and equipment. Additionally, valve actuation leads to substantial cost savings by lowering labor expenses and minimizing downtime, which contributes to long-term financial benefits. Furthermore, the reliability of automated actuators ensures consistent performance, reducing the likelihood of valve failures and maintenance requirements, ultimately enhancing system dependability.

Types of Valve Actuation

- Manual Actuation: Utilizes hand valves or wheels to control fluid flow manually.

- Pneumatic Actuation: Employs air pressure to open and close valves or pair with mechanical springs to offer fail-safe capabilities. Commonly used where air is readily available.

- Electric Actuation: Suitable for applications lacking a reliable air source, utilizing electric power to operate the valve.

- Hydraulic Actuation: Utilized in specialized applications such as offshore, subsea, and pipeline operations requiring higher torques and fail-safe capabilities.

Applications for Valve Actuation

Valve actuation systems are integral to providing precision and control in critical processes across numerous industries, including:

- Oil & Gas: Automates the control of valves in pipelines, ensuring precise regulation of flow and pressure. This improves safety and efficiency in both extraction and transportation processes.

- Chemical Processing: Ensures accurate control of chemical flows, minimizing risks and optimizing reactions. This is crucial for maintaining safety and efficiency in complex chemical manufacturing processes.

- Water Treatment: Facilitates the precise regulation of water flow and treatment chemicals, improving the efficiency and reliability of water purification systems. This ensures clean water supply and compliance with environmental standards.

- Power Generation: Enhances control of steam and cooling water flows, ensuring optimal operation of turbines and heat exchangers. This leads to improved efficiency and safety in power plant operations.

- Pharmaceuticals: Provides precise control of fluid handling systems, ensuring consistent product quality and compliance with stringent regulatory standards. This is essential for maintaining the integrity of pharmaceutical manufacturing processes.

Tailored Valve Actuation Solutions

Relevant Industrial offers customized valve actuation solutions designed to meet the specific needs of various industries. Our solutions integrate the latest technologies and are backed by our extensive experience in providing reliable and efficient automation systems.

For more information about our valve actuation,

contact us today