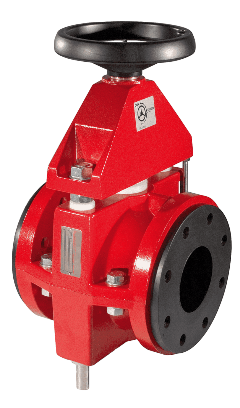

Pinch Valves

Pinch valves are essential components in fluid control systems, particularly known for their ability to handle abrasive, corrosive, and particulate-rich fluids. These valves are designed with a flexible rubber sleeve that can be pinched to control the flow of media, providing an efficient and reliable solution for various industrial applications.

Pinch valves offer several advantages, including a non-clogging design that ensures the valve does not clog, making it ideal for handling slurries, powders, and granular substances. With no internal moving parts in contact with the media, they require minimal maintenance and have a longer lifespan. The rubber sleeve is available in various materials to provide chemical resistance and compatibility with a wide range of fluids. Additionally, pinch valves are easy to operate, with options for manual or automatic operation, offering flexibility and ease of use in different settings.

Pinch valves are constructed with various sleeve materials, such as natural rubber, EPDM, nitrile, and silicone, ensuring compatibility with different media. Their bodies are typically made from cast iron, aluminum, or stainless steel, providing durability and resistance to environmental conditions. For actuation, pinch valves offer manual operation options like handwheel or lever for simple and cost-effective flow control. They also support automated systems with pneumatic, hydraulic, or electric actuators, enhancing operational efficiency and allowing for remote control applications.

Applications of Pinch Valves

- Mining: Pinch valves are widely used in the mining industry to control the flow of slurries, which consist of water and finely ground ore. Their robust design and ability to handle abrasive materials make them ideal for this demanding application.

- Chemical Processing: In chemical processing plants, rubber pinch valves are utilized to manage the flow of aggressive chemicals. Their chemical-resistant sleeves ensure safe and efficient operation, preventing leaks and contamination.

- Pharmaceuticals: Proportional pinch valves offer precise control over fluid flow, which is crucial in pharmaceutical manufacturing. These valves ensure accurate dosing and mixing of ingredients, maintaining the integrity of the production process.

- Water Treatment: Manual pinch valves are often employed in water treatment facilities to regulate the flow of various treatment chemicals and sludge. Their simple design and reliability make them a preferred choice for operators.

Tailored Pinch Valve Solutions

Relevant Industrial is committed to delivering high-quality pinch valves that meet the stringent demands of various industries. Our extensive product portfolio, combined with our engineering expertise, ensures that we provide reliable and efficient solutions for fluid control.

For more information on our pinch valve offerings or to discuss your specific requirements, please, contact us today.