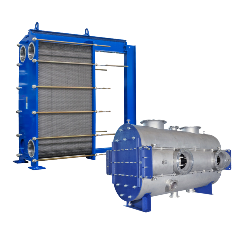

Plate & Frame Exchangers

Plate and frame heat exchangers are highly efficient solutions designed to transfer heat between two fluids without direct contact. Their innovative structure, featuring multiple thin, corrugated metal plates, creates channels for efficient heat transfer. Ideal for various industries requiring reliable temperature regulation, these exchangers offer high thermal performance with a compact design.

These heat exchangers are built for optimal performance, providing exceptional energy efficiency and cost-effectiveness. Composed of metal plates with gaskets or a mechanical frame, these exchangers enable quick assembly and maintenance. Their versatility in handling different pressure and temperature conditions makes them ideal for a wide range of applications, from industrial processing to HVAC systems.

Key benefits of plate and frame exchangers include compactness, ease of cleaning and maintenance, and high heat transfer rates. The design enables rapid temperature adjustments and efficient use of space, making them suitable for industries aiming to maximize both performance and economic value.

Applications of Plate & Frame Exchangers

Plate and frame heat exchangers are integral in industries where heat management is critical. They offer adaptable and efficient solutions for various applications, ensuring consistent performance and energy savings.

Food and Beverage Processing

Plate and frame exchangers are used for pasteurization and temperature control in food and beverage production. Their efficient heat transfer helps maintain the quality of heat-sensitive products while optimizing energy use.

HVAC Systems

These exchangers play a pivotal role in heating and cooling systems by transferring heat between air and fluid, ensuring optimal indoor climate control. Their compact design enables integration into a wide variety of HVAC setups, enhancing energy efficiency.

Chemical Processing

In chemical industries, plate and frame exchangers regulate temperatures during reactions and processes. Their ability to handle varying pressure levels while ensuring maximum heat transfer helps maintain precise process control and safety.

Pharmaceutical Production

Maintaining controlled temperatures is crucial for pharmaceutical processes to ensure product stability. Plate and frame heat exchangers offer a sterile environment for effective temperature management during manufacturing and formulation stages.

Industrial Waste Heat Recovery

Plate and frame exchangers facilitate the recovery of heat from industrial exhaust streams, which can then be reused for preheating purposes. This process lowers energy consumption and reduces operational costs.

Tailored Plate & Frame Exchanger Solutions

At Relevant Industrial, we understand the importance of reliable and efficient thermal management. With our extensive experience in providing industrial solutions, we offer customized plate and frame heat exchanger systems designed to meet the unique requirements of your operations. Whether it’s enhancing process efficiency or ensuring compliance with industry standards, our experts are here to guide you.

Contact us today to learn more about our tailored solutions and comprehensive support services.