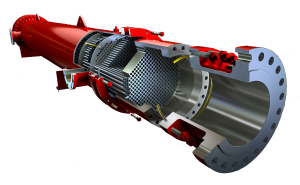

Standard Shell & Tube Heat Exchangers

Standard shell and tube heat exchangers are fundamental to efficient thermal energy management in many industrial operations. These units are designed to transfer heat between two fluids, enhancing energy efficiency and maintaining operational stability in various processes. Renowned for their robust design and adaptability, standard shell and tube heat exchangers play a critical role in applications requiring consistent and efficient thermal regulation.

Manufactured with precision and adhering to industry-leading quality standards, these heat exchangers consist of a cylindrical shell encompassing a bundle of tubes. The tube bundle allows for the effective transfer of heat between fluids, maximizing thermal performance while minimizing energy loss. This straightforward design not only supports high-pressure and high-temperature applications but also allows for easy maintenance and customizability.

Standard shell and tube heat exchangers are valued for their numerous benefits, which contribute to improved operational efficiency and reduced costs. Their robust design supports high mechanical stress, making them suitable for challenging industrial environments. Additionally, their versatility in material selection ensures compatibility with various process fluids, extending their range of applications. The efficient heat transfer capability leads to enhanced energy utilization, optimizing overall plant performance. Lastly, straightforward maintenance procedures help reduce downtime, enhancing the reliability and longevity of operations.

Applications of Standard Shell & Tube Heat Exchangers

These heat exchangers are highly adaptable and find use in numerous industries where effective heat transfer is essential. Below are some key applications and industries that benefit from standard shell and tube heat exchangers:

Petrochemical Industry

Standard shell and tube heat exchangers are crucial for the safe and efficient transfer of heat during the refining and processing of petroleum products. Their robust design withstands high temperatures and pressures, making them ideal for demanding environments.

Power Generation

Used extensively in power plants, these heat exchangers help manage thermal energy in processes like steam condensation and heat recovery. This contributes to higher efficiency in electricity production, reducing fuel consumption and operational costs.

HVAC Systems

In large-scale heating, ventilation, and air conditioning systems, standard shell and tube heat exchangers regulate temperature efficiently. Their reliable design ensures that HVAC systems maintain optimal performance while reducing energy expenditure.

Food and Beverage Industry

Heat exchangers facilitate pasteurization, sterilization, and temperature control in food processing operations. The design supports safe and sanitary handling of products, complying with strict industry standards to maintain quality.

Chemical Processing

Chemical plants rely on these exchangers for controlled heating and cooling of substances. Their ability to handle corrosive fluids and maintain precise temperature control ensures safety and product consistency in chemical reactions.

Marine Applications

Used in shipboard systems for engine cooling and fresh water production, shell and tube heat exchangers demonstrate their adaptability to harsh and variable marine conditions. The durable construction supports long-term use despite exposure to seawater.

Pharmaceutical Industry

Temperature control is vital in pharmaceutical production to ensure the stability and efficacy of active ingredients. Standard shell and tube heat exchangers maintain precise thermal conditions during various stages of drug formulation.

Tailored Standard Shell & Tube Heat Exchanger Solutions

At Relevant Industrial, we offer tailored solutions to meet the specific requirements of your operations. With decades of industry expertise, our team provides guidance and support to help you select the best heat exchanger configuration for your process needs. Our standard shell and tube heat exchangers are manufactured to deliver consistent performance, leveraging proven technology to enhance your facility's energy efficiency and productivity.

Contact us today to learn more about how we can optimize your thermal management solutions.