Steam Surface Condensers

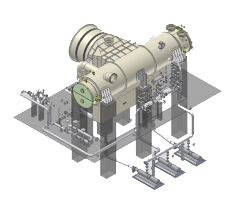

Steam surface condensers play a critical role in industrial and power generation systems by converting steam back into water for reuse. These condensers are essential components for ensuring optimal performance and efficiency in thermal and steam power applications. With a design focused on durability and effectiveness, steam surface condensers support sustainable energy practices by maximizing heat recovery and maintaining pressure balance.

Constructed from high-quality, corrosion-resistant materials, steam surface condensers are built to withstand the demanding environments of power plants and industrial facilities. Their design typically includes a network of tubes that facilitate the heat transfer process, ensuring the condensation of steam back to liquid efficiently. These condensers are adaptable to varying sizes and capacities, making them suitable for both large-scale power generation and smaller industrial processes.

The use of steam surface condensers provides numerous operational benefits. They enhance the overall efficiency of steam turbines by maintaining optimal back pressure, which in turn supports energy savings and reduced operational costs. Their design ensures effective heat recovery, contributing to sustainable energy management and minimizing water waste. The adaptability of these systems to different industrial needs makes them a versatile solution for diverse thermal applications.

Applications of Steam Surface Condensers

Steam surface condensers are utilized across multiple industries and applications due to their robust construction and high efficiency. These condensers ensure reliable operation and energy optimization in various settings. Below are the main industries where steam surface condensers play a pivotal role:

Power Generation

Steam surface condensers are integral in power plants, working in tandem with steam turbines to condense exhaust steam into water. This process helps maintain the turbine's efficiency by creating a vacuum that optimizes the steam cycle.

Petrochemical Processing

In petrochemical facilities, steam surface condensers are used to recover and reuse water, aiding in efficient heat management during processes such as distillation and chemical reactions.

Refineries

Condensers are critical for converting steam produced during refining operations back into water. This step helps maintain energy efficiency and supports the seamless functioning of equipment.

Food and Beverage Industry

Steam surface condensers are utilized to support heating and cooling processes in food production. By efficiently condensing steam, they help maintain precise temperature control essential for high-quality output.

HVAC Systems

In large-scale heating, ventilation, and air conditioning (HVAC) setups, steam surface condensers play a role in managing energy transfer and maintaining climate control in commercial and industrial buildings.

Tailored Steam Surface Condenser Solutions

At Relevant Industrial, we offer tailored solutions for steam and thermal management needs. With years of industry expertise, we ensure that our products, such as steam surface condensers, align with the rigorous demands of modern power and industrial facilities. Our team is equipped to assist you in finding the right condenser to improve your operational efficiency.

Contact us today to learn more about how we can optimize your energy systems and support your sustainability goals.