Pressure Regulators

Pressure regulators are indispensable components in semiconductor manufacturing, playing a vital role in controlling the flow of gases used throughout the chip fabrication process. At Relevant Industrial, we offer a range of Parker Hannifin Veriflo pressure regulators designed specifically for the semiconductor industry, ensuring precise control, minimal contamination, and superior durability in ultra-clean environments.

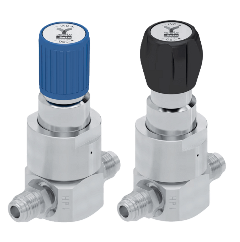

Parker Veriflo pressure regulators are designed to meet the stringent demands of semiconductor manufacturing. Featuring an internally threadless design, these regulators minimize contamination and reduce purge times, making them ideal for ultra-high purity environments where cleanliness is crucial. Constructed from high-performance materials such as Hastelloy C-22®, Inconel®, and Elgiloy®, these regulators provide exceptional corrosion resistance, ensuring durability and reliability even when used with highly reactive gases.

Precision control is another hallmark of Parker Veriflo regulators. With available flow capacities (Cv) ranging from 0.02 to 0.15, these regulators offer precise pressure adjustments critical for maintaining stable gas flows during semiconductor processes. Additionally, Parker’s regulators are compliant with ISO 9001 and NACE MR0175 standards, ensuring that they meet the highest levels of quality, safety, and performance required in the semiconductor industry.

Applications of Pressure Regulators

In semiconductor fabrication, maintaining stable and precise gas flow is critical to the integrity of each step in the production process. Parker Hannifin’s Veriflo pressure regulators are specifically designed to handle the demands of gas management in the semiconductor industry, providing reliable performance in ultra-clean environments. Here are key areas where Parker’s pressure regulators are used in semiconductor manufacturing:

Chemical Vapor Deposition (CVD):

Pressure regulators control the flow of reactive gases during the deposition of thin films on semiconductor wafers, ensuring precise layer formation for high-performance devices.

Etching Processes:

During etching, precision regulators maintain the stable delivery of etching gases, such as chlorine or fluorine-based compounds, to ensure the accurate patterning of microchips.

Gas Distribution for Photolithography:

In photolithography, accurate gas control is essential to achieving precise patterns on semiconductor wafers. Parker Veriflo regulators ensure stable nitrogen and clean dry air (CDA) flow, preventing contamination and defects during the exposure and development process.

General Process Gas Management:

From bulk gas delivery to individual gas lines for argon, nitrogen, and other inert gases, Veriflo pressure regulators maintain constant pressure to keep semiconductor manufacturing processes running efficiently without interruptions.

High-Purity Gas Management:

The semiconductor industry requires gases to be delivered with high precision and minimal contamination. Parker’s regulators are designed to meet these stringent purity standards, ensuring the consistent flow of gases like Plant Nitrogen and Clean Dry Air (CDA) essential for critical processes like oxidation, annealing, and doping.

Tailored Pressure Regulator Solutions

With a focus on the semiconductor industry, Relevant Industrial offers tailored pressure regulator solutions that align with the strict purity and precision requirements of semiconductor fabrication. Whether you need regulators for gas distribution systems, chemical vapor deposition, or high-purity gas lines, our experts can provide customized solutions to enhance your process efficiency and product quality.

Our commitment to providing the best pressure regulators for semiconductor applications ensures that your facility meets the highest standards for performance and reliability.

Contact us today to learn more about Parker Veriflo pressure regulators and how they can be integrated into your semiconductor manufacturing process.