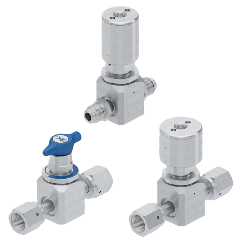

UHP Diaphragm and Bellows Valves

Parker Hannifin's Veriflo Division offers UHP (Ultra-High Purity) Diaphragm and Bellows Valves, specifically engineered to meet the exacting demands of semiconductor manufacturing processes. These valves are designed to handle ultra-high purity gases and chemicals with minimal particle generation and contamination, ensuring the highest level of cleanliness and process control required in semiconductor fabrication environments. With pressure ratings up to 3500 psig, their robust construction and superior sealing technology allow for consistent, high-precision performance in cleanroom settings where even the slightest impurity can impact product quality. Key benefits include long cycle life, corrosion resistance, and reliable operation in high-temperature environments, ensuring uninterrupted performance in semiconductor production.

Applications of UHP Diaphragm and Bellows Valves in Semiconductor Manufacturing

In semiconductor manufacturing, maintaining ultra-high purity is critical to the production of microchips, integrated circuits, and other advanced electronic components. Parker Veriflo's UHP Diaphragm and Bellows Valves play a pivotal role in achieving this by providing unparalleled control over the flow of gases and chemicals that are essential to semiconductor fabrication processes. Below are some of the key applications within the semiconductor industry:

Wafer Processing:

Semiconductor wafers require precise deposition of materials like silicon, metals, and oxides, which must be delivered without contamination. Parker Veriflo’s UHP valves ensure ultra-clean gas and chemical delivery for processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and plasma-enhanced CVD. The exceptional sealing properties of these valves prevent particle generation and ensure a pristine environment during deposition.

Etching and Cleaning:

The etching process, used to define the microscopic patterns on semiconductor wafers, demands absolute purity to avoid defects in the etching profiles. UHP Diaphragm and Bellows Valves maintain a controlled and clean flow of reactive gases during etching and during the subsequent cleaning stages where hazardous chemicals are used to remove unwanted materials. Their low internal volume design minimizes the risk of contamination and maintains consistent flow rates during these critical processes.

Gas Distribution Systems:

The precise and contaminant-free distribution of gases like nitrogen, oxygen, hydrogen, and argon is crucial for various stages of semiconductor fabrication. Parker Veriflo’s UHP valves are integral components of gas distribution systems, providing leak-tight performance and the ability to handle high-pressure applications. Their robust design ensures consistent gas purity from the source to the point of use, reducing the risk of contamination at every stage of the process.

Chemical Mechanical Planarization (CMP):

CMP is a process used to smooth and planarize the surface of semiconductor wafers. Parker Veriflo’s UHP valves control the flow of slurry chemicals used in CMP, ensuring precise delivery with no risk of particle contamination. Their corrosion-resistant construction ensures long-lasting performance even when exposed to harsh chemicals used in the planarization process.

Photolithography:

In photolithography, where light-sensitive chemicals are used to transfer circuit designs onto wafers, any contamination can result in defective chips. UHP Diaphragm and Bellows Valves ensure ultra-pure chemical delivery during the photolithographic process, safeguarding the precision and clarity of pattern transfers essential for microchip production.

Tailored UHP Diaphragm and Bellows Valve Solutions

Parker Hannifin's Veriflo Division offers custom solutions for semiconductor manufacturers who require the highest level of purity and control. With decades of experience in the industry, Parker Veriflo can provide tailored UHP valve configurations to meet the specific demands of your gas and chemical delivery systems. Whether it’s for wafer processing, etching, or photolithography, our valves are designed to deliver optimal performance under the most stringent conditions.

Contact us today to discover how our UHP Diaphragm and Bellows Valves can enhance the efficiency and reliability of your semiconductor manufacturing operations.